CR53 Hydraulic Compression Tool

Find CR53 Hydraulic Compression Tool at CRIMPER. Electrical terminal lines specially developed to meet the highest standard of requirements. Products of the utmost reliability and efficiency. Operation without energy loss, providing cost reduction and increased profitability.

Technical Information:

CR53 Hydraulic Compression Tool

Compresses uninsulated terminal lugs and tubular sleeves from 10.00 to 240.00 mm².

Compression: Hexagonal | Capacity: 6 tons.

Length: 36.0 cm | Width: 31.0 cm | Weight: 3.500 kg

Examples of terminals crimped with this tool:

AT7217 AT7234 AT7271 AT7325 AT7588 AT7597 AT7024 AT7114 AT7131 LT7912 LT7924 LT7934

Included Accessories:

1 Conductor wire for connecting the charger to the 220 V socket

1 Battery charger for 220 V

1 Battery (approximate lifespan in continuous use – 6 months)

1 set of dies containing sizes 10, 16, 25, 35, 50, 70, 95, 120, 150, 185, and 240 mm2

Operation Mode

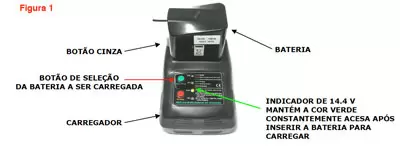

Charging the Battery

Connect the charger to a 220 V socket.

Note that the red light on the top of the charger will start blinking.

Select the type of battery to be charged by pressing the green button until the light blinks where 14.4 V is marked.

Insert the battery into the charger as shown in Figure 1.

Note that the light stops blinking and remains constantly green.

Once the battery is fully charged, a “beep” will be emitted.

Usually, the charging time is approximately 30 minutes.

With the battery fully charged, its charge lasts up to 150 crimps.

2) Inserting and Removing the Battery in the Pliers Insert the battery at the bottom of the pliers as shown in Figure 2. A ‘click’ will be heard when it is properly inserted. To remove it, press the gray side button and pull it (Figure 2).

3) Inserting and Removing the Dies in the Pliers Select the correct die according to the conductor and terminal to be used. Note that all the dies have the size number in mm2 engraved. Fit the dies as shown in Figure 3. To remove the dies, pull them manually.

4) Crimping To crimp a terminal, press the black activation button as shown in Figure 4, with the terminal and conductor inserted into the pliers. Note that the side LEDs light up, indicating the battery charge level (Figure 4).

Pliers Disarmament

After crimping the terminal, press the red disarm button (Figure 4), and the piston will be released. If it doesn’t release due to the crimping force, press the red disarm button and the black activation button together.

MAINTENANCE

Hydraulic oil replacement is done by unscrewing and removing the fixed pliers cable (6).

Inside the cable cylinder, you can see a white, yellow, or black device (7). It’s the oil reservoir cap (8).

Removing this cap allows you to add the necessary oil for the pliers’ operation.

QUESTIONS

Contact us at the following phone numbers: (19) 3246-1722 or 0800-772-1777.

DO NOT OPERATE THE PLIERS WITHOUT THE DIES.

Crimper: Quality is our brand!

Crimper was founded on September 1, 1981, in the city of Campinas, SP, by Mr. Arturo Andreiuk, and since its inception, it has specialized in the manufacture and sale of electrical terminals and connectors, serving the industrial market of Brazil and Latin America. Over the years, the company has improved its product line, quality processes, and production for an increasingly demanding market, requiring significant investments in labor and more efficient machinery from its partners. Today, with a manufacturing plant of over 5,000 m², Crimper supplies products to the largest electro-electronic industries in Brazil and is positioned among electricians and electrical materials merchants as the company that delivers the highest quality terminals in the national market. Crimper believes in Brazil and continues to invest in order to further improve its processes and products, ensuring continuous and sustainable growth.