CR52 Hydraulic Compression Tool

Find CR52 Hydraulic Compression Tool at CRIMPER. Electrical terminal lines specially developed to meet the highest standard of requirements. Products of the utmost reliability and efficiency. Operation without energy loss, providing cost reduction and increased profitability.

Technical Information:

Hydraulic Compression Tool CR52

Crimps terminal lugs and tubular sleeves from 10.00 to 185.00 mm².

Hexagonal compression | Capacity: 6 tons.

Length: 60.5 cm | Width: 14.0 cm | Approximate weight: 4.460 kg.

Examples of terminals crimped with this tool:

AT7217, AT7234, AT7271, AT7325, AT7588, AT7597, AT7024, AT7114, AT7131, LT7912, LT7924, LT7934

Operating Procedure:

1) Matrices Selection

Select the matrices to be used (through the nest marking on the matrix – Fig.1), according to the gauge of the terminal or tubular sleeve to be crimped.

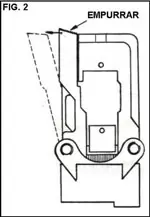

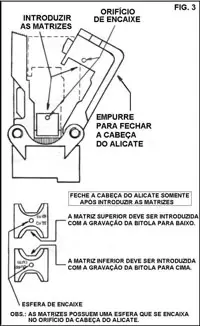

2) Installation of Matrices

After selecting the matrices, open the head of the pliers (Fig.2) and insert the matrix so that the gauge marking faces outward (Fig.3). After the operation, close the head of the pliers (Fig.3).

3) Crimping

Crimping is done by moving the pliers’ handle (Fig.4). The matrices will compress the terminal with each movement of the pliers’ handle until the 6 tons are applied.

The operation is complete when the pliers emit an easily noticeable “click.”

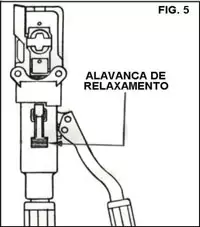

4) Pliers Disarm

After crimping, the pliers are disarmed by pressing the relaxation lever against the pliers’ body (Fig.5).

Automatically, the matrices will return to the position they were in before the start of crimping, releasing the terminal.

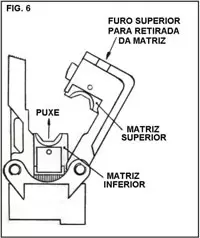

5) Matrices Removal

After disarming the pliers, the matrices are removed as follows:

– Remove the matrix at the bottom of the pliers’ head by pulling it up (Fig.6).

– Remove the matrix at the top of the pliers’ head by inserting an object into the upper hole of the head and pressing down (Fig.6).

– Close the pliers’ head again as seen in Fig.3.

MAINTENANCE

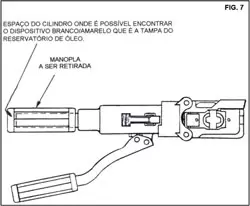

The replacement of hydraulic oil is done by removing the handle from the pliers’ body (Fig.7).

Inside the cable cylinder, you can observe a white or yellow device. It is the oil reservoir cap.

By removing this cap, you can add the necessary oil for the pliers’ operation.

OBSERVATIONS

The head of the hydraulic pliers CR52 has a 180º rotation to position the tool in the most suitable crimping position.

DO NOT OPERATE THE PLIERS WITHOUT THE MATRICES.

Crimper: Quality is our brand!

Crimper was founded on September 1, 1981, in the city of Campinas, SP, by Mr. Arturo Andreiuk, and since its inception, it has specialized in the manufacture and sale of electrical terminals and connectors, serving the industrial market of Brazil and Latin America. Over the years, the company has improved its product line, quality processes, and production for an increasingly demanding market, requiring significant investments in labor and more efficient machinery from its partners. Today, with a manufacturing plant of over 5,000 m², Crimper supplies products to the largest electro-electronic industries in Brazil and is positioned among electricians and electrical materials merchants as the company that delivers the highest quality terminals in the national market. Crimper believes in Brazil and continues to invest in order to further improve its processes and products, ensuring continuous and sustainable growth.