When choosing the ideal electrical terminal for your project, it’s crucial to pay attention to certain details that make all the difference. In this very special article from the Crimper do Brasil Blog, we will discuss the importance of electrical terminals and connectors in installations.

4 steps to determine if terminals are of good quality:

1. First, we recommend checking the packaging of the terminals to see if they were manufactured for mm² or in AWG/MCM format. Don’t know what format this is? Don’t worry; we’ll explain this subject better!

2. Nowadays, terminals are manufactured for up to 1000V, so it’s essential to check the working voltage for which the terminal will be used.

3. According to the current regulations in Brazil, the working temperature of the terminal should be between 70 to 90 degrees Celsius. Keep this information in mind when choosing the right terminals.

4. Request the product certificate. If the seller does not provide this information, consider purchasing the terminals from another store. Did you know that all Crimper products come with a certificate? This highlights the importance of electrical terminals and connectors in installations.

The Danger of Undersized Cables and What is AWG/MCM

Have you ever encountered undersized cables? Many times, we buy cables labeled as 2.5mm, but in reality, they are only 2mm. This is not only an annoying situation, but the same issue also occurs with electrical terminals because there are no exclusive technical standards for electrical terminals manufactured in Brazil (as is the case with cables, circuit breakers, wires, and more).

As a result, many low-quality imported products find their way into our market. Brazil uses the unit of measurement for cables and terminals in square millimeters, while in many other countries, the AWG/MCM unit is used. This leads to differences in conductor conditions. Therefore, it is not suitable to use imported terminals in AWG/MCM format because they were not naturally manufactured to withstand the current supply conditions in Brazil.

Insulated terminals for square millimeters (mm2) are made to withstand 1000V, whereas AWG/MCM format terminals are manufactured to handle 600V. To determine if the material is genuinely insulating, just examine the terminals and check if they have insulation burrs and fissures. These are important details to look out for.

Did you know that terminals should be made of electrolytic copper?

They should be made from the same material as copper cables. Therefore, avoid terminals made from other materials like brass, which can be very dangerous. This is because when we crimp the end of a cable to use it in a terminal, all the electrical current reaching the end of that cable will divert from the cable to pass through the terminal and enter the connection point, whether it’s a busbar, a component, or a circuit breaker. This can cause heating.

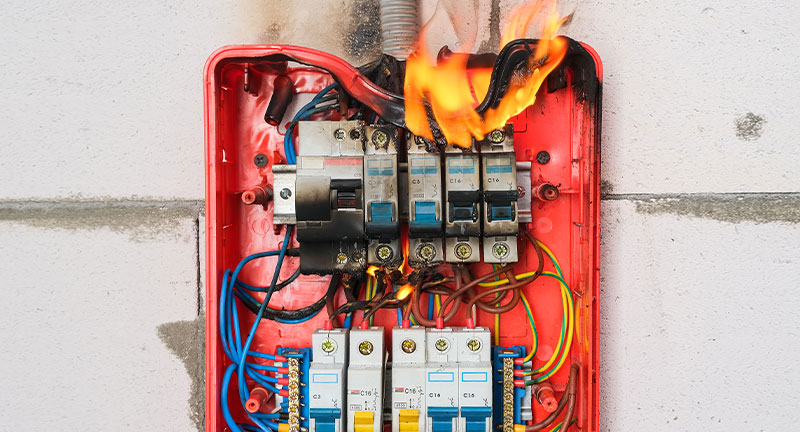

The danger in electrical installations lies in the connections. If you use inappropriate terminals, you may compromise all your components. The result? Circuit breakers catching fire or short-circuiting, busbars experiencing various issues, and other headaches that can be avoided. Many of these overloads can be caused by the use of inappropriate terminals.